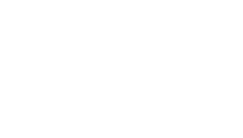

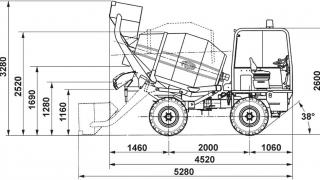

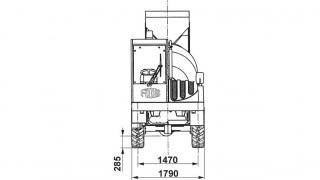

Self Loading Concrete Mixer

DB 180

High productivity machine with small dimensions, therefore suitable for large jobs with unsurpassed agility and stability.

1.8 cu.m

Batch Capacity

36.9 kW (49 Hp)

Max. Power

4x4 FOUR WHEEL DRIVE

Drive

45 cu.m

Avg. 8 hour production capacity

High productivity machine with small dimensions, therefore suitable for large jobs with unsurpassed agility and stability. This is due to the four-wheel drive, articulated frame and differential swiveling axle. The DB180 ensures yield of 1.8 m³ in every batch. The DB 180 enables production of high quality concrete at any urban site or a remote inaccessible site. It is an economic & user-friendly machine with high productivity rating. This makes it ideal for rental and maintenance works in inaccessible areas.

Features

Specification

DIESEL ENGINE

Make (Model)

YANMAR 4TNV88

Max. power

36.9 kW / 49 Hp

Adj. power

32 kW / 44 Hp @ 2,600 rpm

Max. torque

139 Nm @ 1,200 rpm

Bore/stroke

88/90 mm

4 cylinders - total displacement

2,190 cc

Injection

Mechanical control with direct injection

Cooling System

Water cooling, dry air filter

Emission

Directive 2004/26/CE - Stage III A

ELECTRIC SYSTEM

Alternator

12 V - 40 A

Battery

12 V - 80 Ah (400 A)

Road light system.

4X4 FOUR-WHEEL DRIVE

Hydrostatic “automotive” transmission with variable displacement pump and variable displacement hydraulic motor with electrohydraulic control.

Electro-hydraulically controlled mechanical gearbox for “working speed” and “road transfer” speed.

SPEED

forward gears

4

1ST

0 - 5.0 Km/h

2ND

0 - 7.2 Km/h

3RD

0 - 14.2 Km/h

4TH

0 - 20.2 Km/h

REVERSE GEARS

2

1ST

0 - 5.0 Km/h

2ND

0 - 5.0 Km/h

3RD

0 - 14.2 Km/h

4TH

0 - 14.2 Km/h

Traction / weight ratio

55%

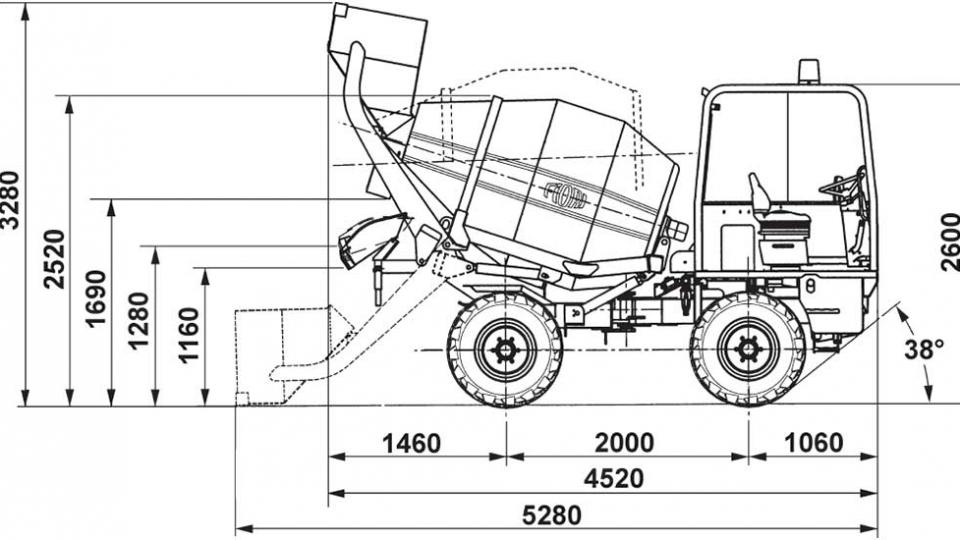

AXLES AND WHEELS

Front load-bearing, oscillating (± 7°) with planetary reduction gears on the wheel hubs.

Rear load-bearing with planetary reduction gears on the wheel hubs and directly flanged gearbox.

Tyres

12.0/75-18 12PR

BRAKES

Internal oil-bath disc service and emergency brakes acting on the 4 wheels, activation with pump on independent dual circuit.

Drum parking brake on the front axle with lever control.

EQUIPMENT HYDRAULIC SYSTEM

Gear pump

Max. flow rate

35 litres/min

Maximum pressure

170 bar

3-element distributor with joystick.

Aluminium heat exchanger for hydraulic oil cooling.

Pressurised closed-circuit intake with oil fi lter replaceable from the outside.

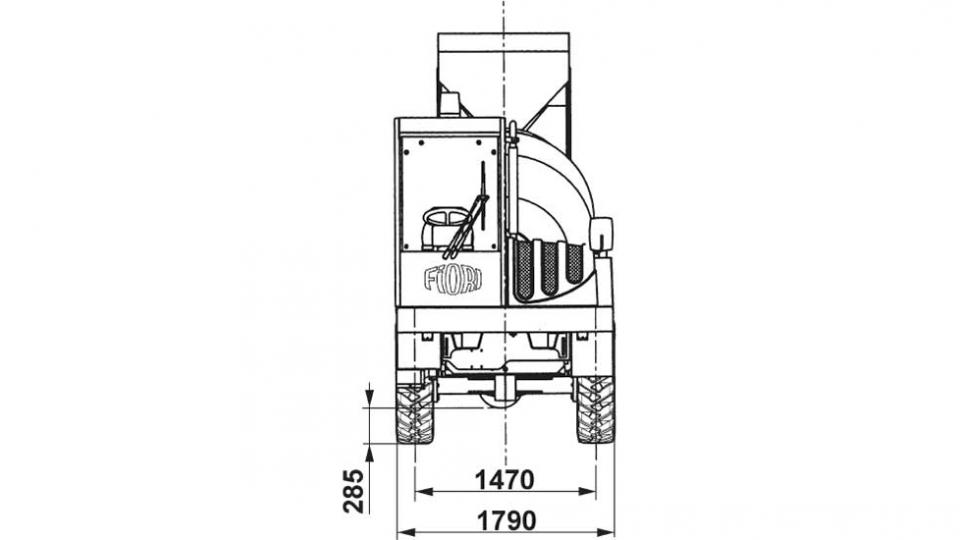

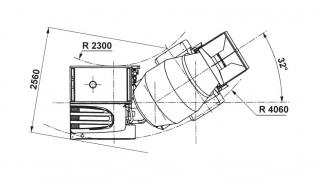

MIXING AND POURING

Double-cone drum with double-spiral mixing screws.

Geometrical drum volume

2,560 litres

Drum rotation speed

20 rpm

Class S1 concrete produced as

1.8 cu m

Drum rotation by means of a piston pump with variable fl ow rate and an orbital hydraulic motor in closed circuit with infinitesimal electrical control positioned in the cabin and at the rear of the machine.

Drum raising up to the horizontal position by means of 2 double-acting jacks .

Chute with manual tilting independent of the mixing drum inclination and 180° rotation. Removable chute, for direct unloading from hopper.

1 chute extensions provided as standard equipment.

WATER SYSTEM

“Self-priming” volumetric water pump with quick-suction.

Max. capacity

140 litres/min

Maximum head

3 bar

Water tank capacity

240 litres

Mix Control system for programmable and controlled management of water feeding to the drum and of mixing and unloading from the ground panel.

Water feeding to the drum controlled by means of electromagnetic flow meter and fed litre reading on both the cabin display and at the rear of the vehicle.

Water pump activation from the driver’s seat and from the ground panel. Suction selection from the ground with quick-coupling pipes.

LOADING SHOVEL

Loading arms with fixed loader and automatic unloading hatch.

Volumetric capacity

470 litres

Number of shovelfuls per load

5 to 6

Production capacity

up to 4 cycles/hour

CABIN

Open cab designed according to ROPS & FOPS Lev. I criteria, windows on three sides.

180° pivoting driving post.

Anatomic seat with flexible suspension and height adjustment, seat belts.

Driving and equipment controls with ergonomic arrangement.

SERVICE REFILL CAPACITIES

Fuel tank

46 litres

Total hydraulic system capacity

67 litres

Engine oil

7.07 kg

WEIGHTS

Operatingweight

3,700 kg

Max. gross weight

8,400 kg

Load-carrying capacity

4,700 kg