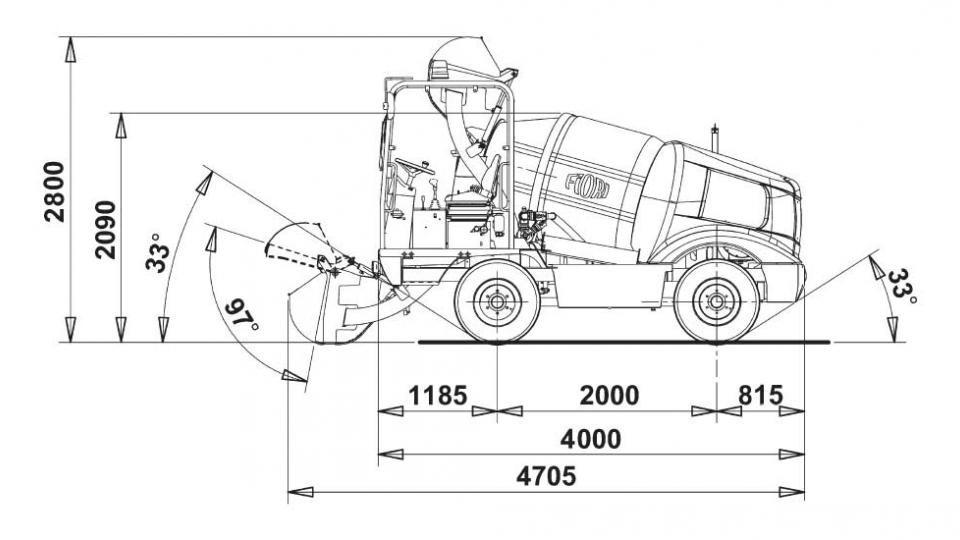

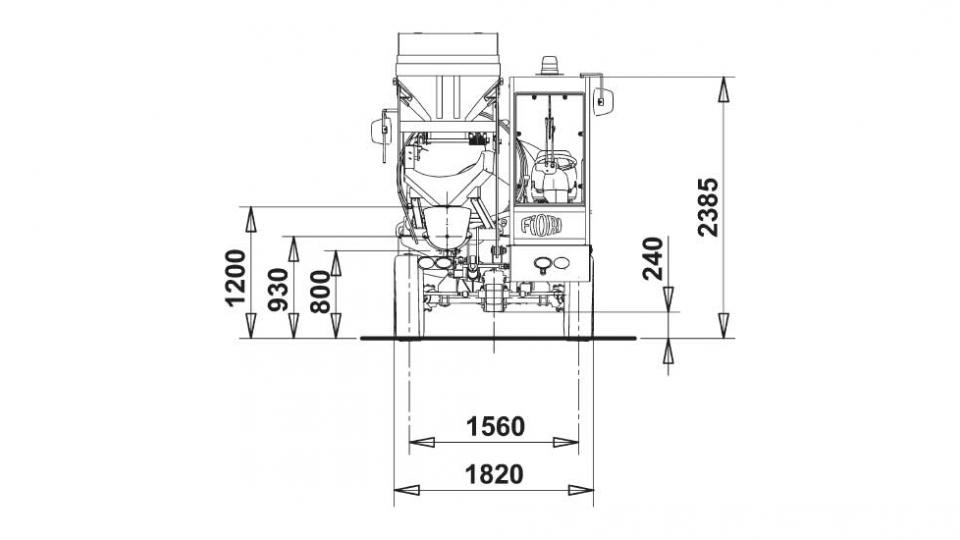

Self Loading Concrete Mixer

DB X10

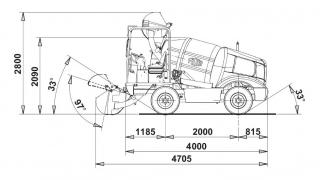

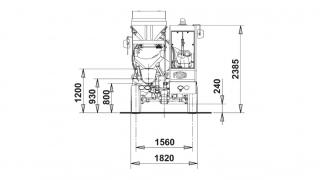

DB X10 with a yield of 1.0 m³, in every batch, is the most productive & compact model with front-loading version.

1.0 cu.m

Batch Capacity

30kW (42 HP)

Max. Power

4x4 FOUR WHEEL DRIVE

Drive

32 cu.m

Avg. 8 hour production capacity

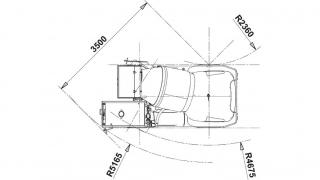

Among the small-sized, self loading concrete mixers, the DB X10 with a yield of 1.0 m³, in every batch, is the most productive & compact model with front-loading version. With unparalleled agility, the DB X10 with its glazed spacious cabin provides great operator comfort. The DB X10 is designed as an alternative to manual concrete mixers. However, it sets itself apart by its productivity and quality of concrete produced. The DB X10, in fact, is the 'origin' of the concept of self loading concrete mixer.

Features

Specification

DIESEL ENGINE

Model

KOHLER series 1,903M

Type

Aspirated

Total displacement, no Cylinders

1,861cc - 3 in line

Injection

Direct with mechanical control

Cooling

air water, dry air filter

Max. power

30 kW (42 Hp)

Adj. power

30 kW (42 Hp) (2,600 rpm)

Max. torque

130 Nm @ 1600 rpm

Alternator

130 Nm @ 1,600 rpm

ELECTRIC SYSTEM

Battery

12 V - 60 Ah (480 A)

Road light and signalling system

optional

4X4 FOUR-WHEEL DRIVE

Hydrostatic “automotive” transmission with variable displacement pump and variable displacement two-position hydraulic engine with electro-hydraulic control, and reverse gear control on the steering wheel.

SPEED

forward gears

2

1ST

0 - 6.3 Km/h

2nd

0 - 15.3 Km/h

REVERSE GEAR

1

1st

0 - 6.3 Km/h

2nd

0 - 6.3 Km/h

Traction / weight ratio

33%

AXLES AND WHEELS

Rear load-bearing, oscillating (± 7.5°) and non-steering with planetary reduction gears on the wheel hubs.

Front load-bearing, steering with planetary reduction gears on the wheel hubs.

Tyres

10.0/75-15.3 14PR

BRAKES

Internal oil-bath disc service brakes acting on the 4 wheels, activation with pump on single circuit.

Parking and emergency drum brakes on the rear axle with lever control.

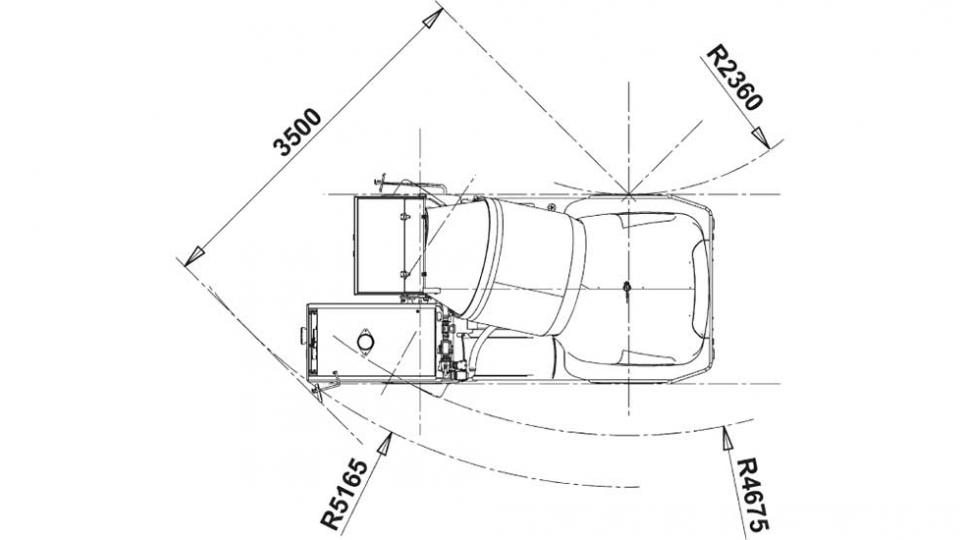

STEERING

Assisted by means of load-sensing power steering on 2 steering wheels.

WATER SYSTEM

“Self-priming” volumetric water pump with quick-suction.

Max. capacity

160 litres/min

Maximum head

4

A steel tank to the left of the machine with a total capacity of 200 litres.

Water feeding to the drum controlled by means of electromagnetic fl ow meter and fed litre reading on the cabin display.

Water pump activation from the driver’s seat.

Suction selection from the ground with quickcoupling pipes.

MIXING AND UNLOADING

Double-cone drum with double-spiral mixing screws.

Geometrical drum volume

1,685 litres

Drum rotation speed

20 rpm

Class S1 concrete produced as

1 cu m

Drum rotation by means of a gear pump and an orbital hydraulic motor in open circuit with electrical control positioned in the cabin.

Unloading chute with mechanical tilting and rotation.

1 unloading chute extension provided as standard equipment.

EQUIPMENT HYDRAULIC SYSTEM

Gear pump

Max. flow rate

21 litres/min

Maximum pressure

180 bar

3-element distributor with joystick to control arms and loader, and lever to control the water pump.

Aluminium heat exchanger for hydraulic oil cooling.

Pressurised closed-circuit intake with oil filter replaceable from the outside.

LOADER

Loading device with grab bucket and lifting arms controlled by double-acting hydraulic cylinders.

Automatic unloading hatch driven by a mechanical lever.

Volumetric capacity

340 litres

Number of loaderfuls per load

around 4

Production capacity

up to 4 cycles/hour

CABIN

Open cab designed according to ROPS & FOPS Lev. I.

Anatomic seat with flexible suspension and height adjustment, seat belts.

Driving and equipment controls with ergonomic arrangement.

SERVICE REFILL CAPACITIES

Fuel tank

50 litres

Total hydraulic system capacity

40 litres

Engine oil

7.5 kg

WEIGHTS

Operating weight

2,880 kg

Max gross weight

5,550 kg

load-carriyng capacity

2,670 kg