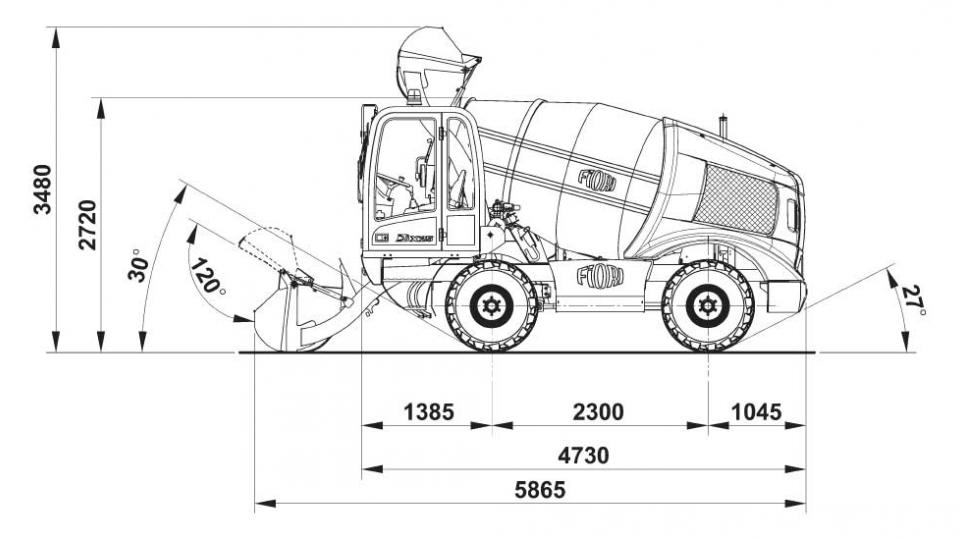

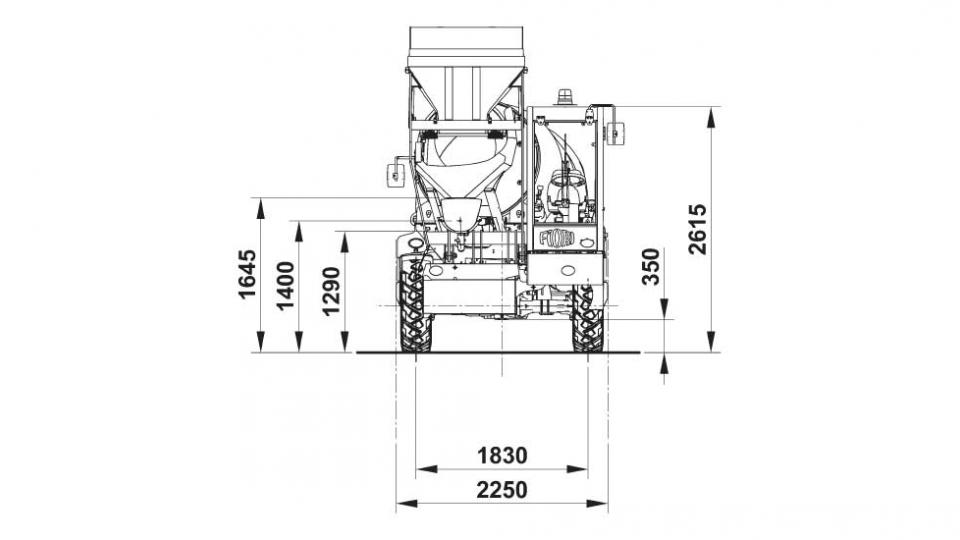

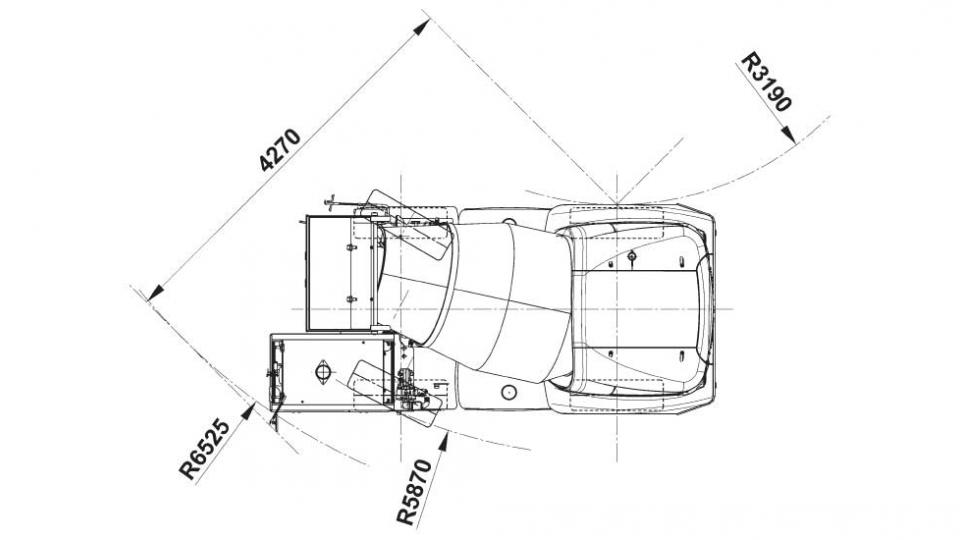

Self Loading Concrete Mixer

DB X25

The DB X25 is the most compact & economical front-end self-loading concrete mixer model on the market.

2.5 cu.m

Batch Capacity

64.5 kW (87 Hp)

Max. Power

4x4 FOUR WHEEL DRIVE

Drive

70 cu.m

Avg. 8 hour production capacity

The DB X25 is the most compact & economical front-end self-loading concrete mixer model on the market. This extremely compact, surprisingly agile & highly stable mixer guarantees a maximum yield of 2.5 m³ of concrete in every batch. The wide cabin windscreen along-with the specially designed loading arms provide high level of visibility. Simplicity of use, compactness and reliability make DB X25 an ideal machine for those who wish to achieve ROI (Return On Investment) through machine rental. This is achieved while delivering high quality concrete using FIORI group's self loading concrete mixers.

Features

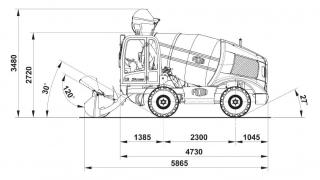

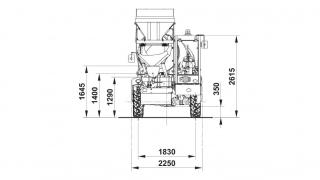

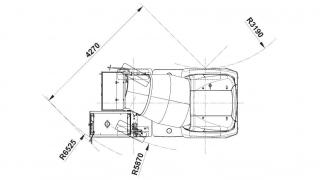

Specification

DIESEL ENGINE

Model

PERKINS series 1,104

Type

Aspirated/Turbo

Total displacement, no Cylinders

4,400cc - 4 in line

Injection

direct with mechanical control

Cooling

air water, dry air filter

Max. power

64.5 kW (87 Hp)/74.5 kW (101 Hp)

Adj. power

64 kW (2,400 rpm)/70 kW (2,200 rpm)

Max. torque

293 Nm @ 1,400 rpm/392 Nm @ 1,400 rpm

Alternator

12 V - 65 A

ELECTRIC SYSTEM

Battery

12 V - 132 Ah (600 A)

Road light system

4X4 FOUR-WHEEL DRIVE

Hydrostatic “automotive” transmission with variable displacement pump and variable displacement hydraulic motor with electrohydraulic control, and reverse gear control on the steering wheel.

Electro-hydraulically controlled mechanical gearbox for “working speed” and “road transfer” speed.

SPEED

forward gears

4

1ST

0 - 3.7 Km/h

2ND

0 - 7.0 Km/h

3RD

0 - 11.0 Km/h

4TH

0 - 24.0 Km/h

REVERSE GEARS

2

1ST

0 - 3.7 Km/h

2ND

0 - 3.7 Km/h

3RD

0 - 11.0 Km/h

4TH

0 - 11.0 Km/h

Traction/Weight ratio

40%

AXLES AND WHEELS

Front and steering with planetary reduction gears on the wheel hubs and flanged gearbox.

Rear, oscillating (± 7°) with planetary reduction gears on the wheel hubs.

Tyres

12.5-18 16PR

BRAKES

Internal oil-bath disc service and emergency brakes acting on the 4 wheels, activation with miniservo pump on independent dual circuit.

Negative type parking brake, with internal oil-bath discs on the rear axle and electro-hydraulically controlled release.

STEERING

Assisted by means of load-sensing power steering on 2 steering wheels.

WATER SYSTEM

“Self-priming” volumetric water pump with quick-suction.

Max. capacity

230 litres/min

Maximum head

4 bar

Two connected tanks positioned opposite each other made of polyethylene with a total capacity of 570 litres.

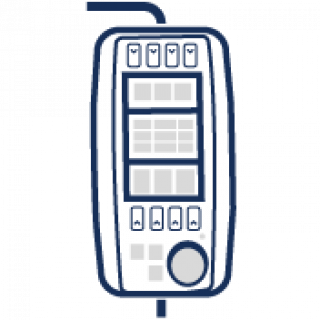

Water feeding to the drum controlled by means of electromagnetic fl ow meter and fed litre reading on the cabin display.

Water pump activation from the driver’s seat.

Suction selection from the ground with quickcoupling pipes.

MIXING AND UNLOADING

Double-cone drum with double-spiral mixing screws and convex bottom.

Geometrical drum volume

3,900 litres

Drum rotation speed

22 rpm

Class S1 concrete produced as

2.5 cu m

Drum rotation by means of a piston pump with variable flow rate and an orbital hydraulic motor in closed circuit with infinitesimal electrical control positioned in the cabin.

Unloading chute with hydraulic tilting by means of a double-acting jack and control placed inside the cabin.

1 unloading chute extension provided as standard equipment.

EQUIPMENT HYDRAULIC SYSTEM

Gear pump

Max. flow rate

40 litres/min

Maximum pressure

230 bar

3-element distributor servo-controlled with multi-function joystick

Aluminium heat exchanger for hydraulic oil cooling

Pressurised closed-circuit intake with oil filter replaceable from the outside

LOADER

Loading device with grab bucket and lifting arms controlled by double-acting hydraulic cylinders.

Automatic unloading hatch driven by a mechanical lever.

Volumetric capacity

560 litres

Number of loaderfuls per load

around 7

CABIN

Closed cab with heating system, designed in accordance with ROPS & FOPS Level I standards.

Tilting front window.

Anatomic seat with flexible suspension and height adjustment, seat belts.

SERVICE REFILL CAPACITIES

Fuel tank

85 litres

Total hydraulic system capacity

113 litres

Engine oil

7.96 kg

WEIGHTS

Operating weight

5,000 kg

Max gross weight

11,000 kg

Load-carrying capacity

6,000 kg