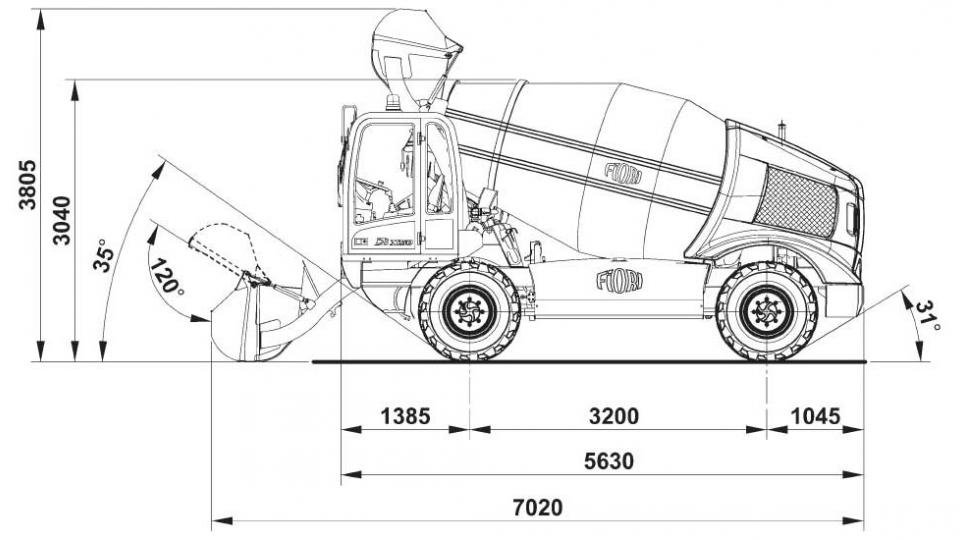

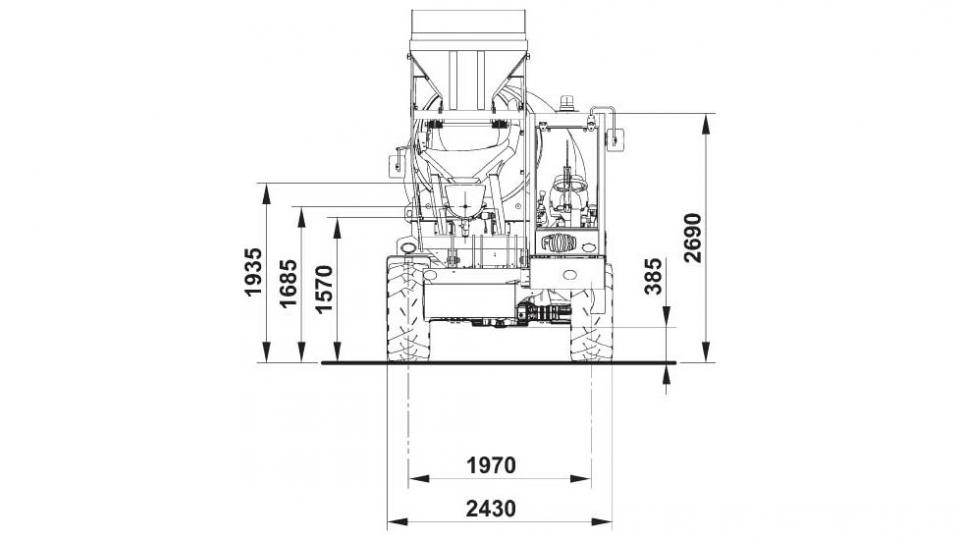

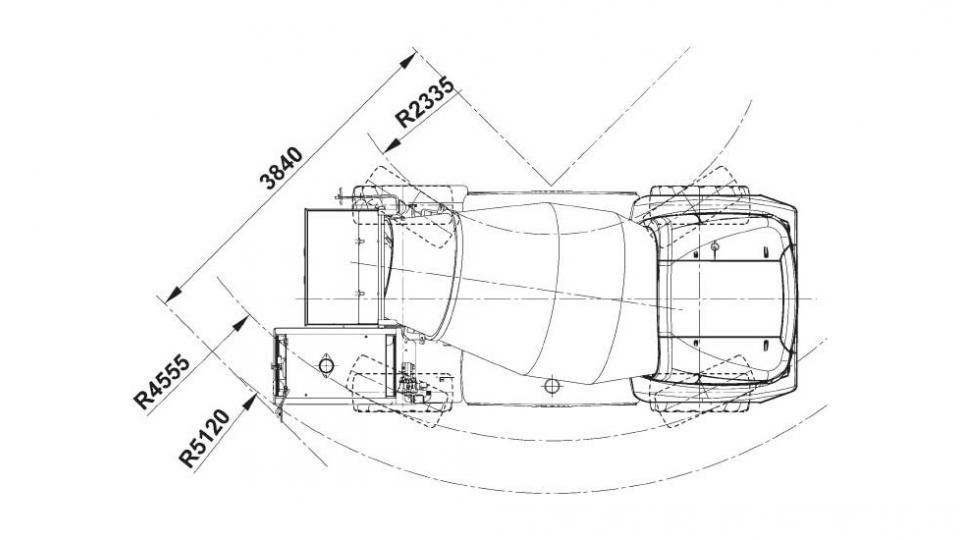

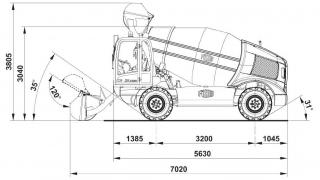

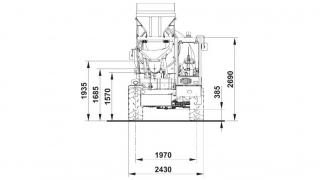

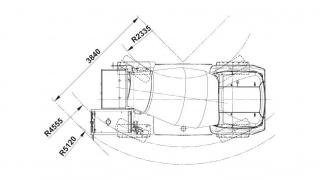

DB X50

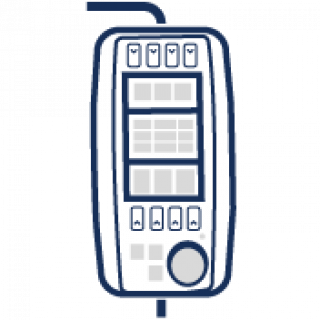

Economy and productivity are the distinctive elements of the DB X50. The DB X50 is the most economical and largest capacity concrete mixer with frontal loading ever made. Compact in size & highly agile, the DB X50 guarantees a maximum yield of 5.0 m³ of concrete in every batch. The unique positioning of the drum and the specially designed loading arm gives enhanced visibility during loading and casting operations. The DB X50 is equipped with an innovative clamshell bucket which maximizes loading efficiency and thereby minimise the batching time. This enables reaching a daily productivity of up to 120-130 m³ of concrete. By equipping the DB X50 with the exclusive computerized batch controller system CBV 2.0, it is possible to obtain the production of certified quality concrete everywhere.